www.buildingsandcities.org/insights/commentaries/reducing-concrete.html

How R&D is Reducing the Use of Concrete

Concrete has high environmental impacts. Can the construction industry reduce the volume of concrete that is used?

After water, concrete is the most widely used substance on earth. Paul Shepherd (University of Bath) explains how deep reductions in the amount of concrete used in buildings can be achieved through advanced structural design and fabrication.

Concrete is an easy target. It responsible for around 8% of the UK's anthropogenic carbon emissions (Lehne 2018, p1), as well as being a significant contributor to the world shortage of sand as a raw material (UNEP 2022). Its climate and environmental impacts are very high and damaging. However, concrete is a very useful material and is ubiquitous in modern construction. It starts life as a liquid, which means it can easily be moulded into complex shapes, and it is very efficient at resisting compressive forces. However, the way concrete is currently used in construction is incredibly wasteful. This is due to the high cost of labour which has led to the design and construction of buildings being focused on ease of construction, standard components and reduced labour. The frugal issue of materials was a historical issue, but this does not figure in the economics of modern construction practice.

A key challenge is whether and how to use less concrete. Researchers at the Universities of Bath, Cambridge and Dundee in the Automating Concrete Production (ACORN) project are developing a new approach to the structural design and fabrication of concrete components. The emphasis is developing highly efficient shapes for concrete beams, columns, floor slabs, etc. that place material where it is most needed for compression. This results in more complex shapes, but significantly less concrete is required. Their main focus to-date has been on commercial and office buildings, where concrete is often used to produce floors on regular grids with 6-12 m spans, generally in combination with raised floors. However, their philosophy of using less concrete by being careful where it is used would be equally beneficial to residential housing, schools and all types of high-rise. The ACORN project was funded through UKRI's 'Transforming Construction Challenge' to achieve the 'Construction 2025 Strategy' targets of increasing project delivery speed and productivity whilst slashing whole-life costs and carbon emissions.

If the shape of a beam can be changed, such that the load is supported by an arch, or the shape of a floor changed to support load with a vaulted shell, then the material can be used as it wants to be, in compression, and needs no steel reinforcement.

ACORN's response was to find innovative ways to fabricate these complex shapes and to overcome the 'harder to make' argument. Part of the solution is to harness the computing power and robotics to automate the process. This in turn implies that the concrete components will need to be made off-site in a factory-like setting (or possibly in a temporary factory installed near-site). Far from being a disadvantage, the move to off-site can bring more consistency, better quality control, improved health and safety and a higher-skilled workforce. Admittedly this does put an upper limit on size of element that can be made in one piece and still transported to site. But the move towards a kit of parts designed for easy assembly on-site can not only make drastic cuts to erection times but also allows parts to be disassembled and reused on refurbishments or new-builds elsewhere, promoting a circular economy.

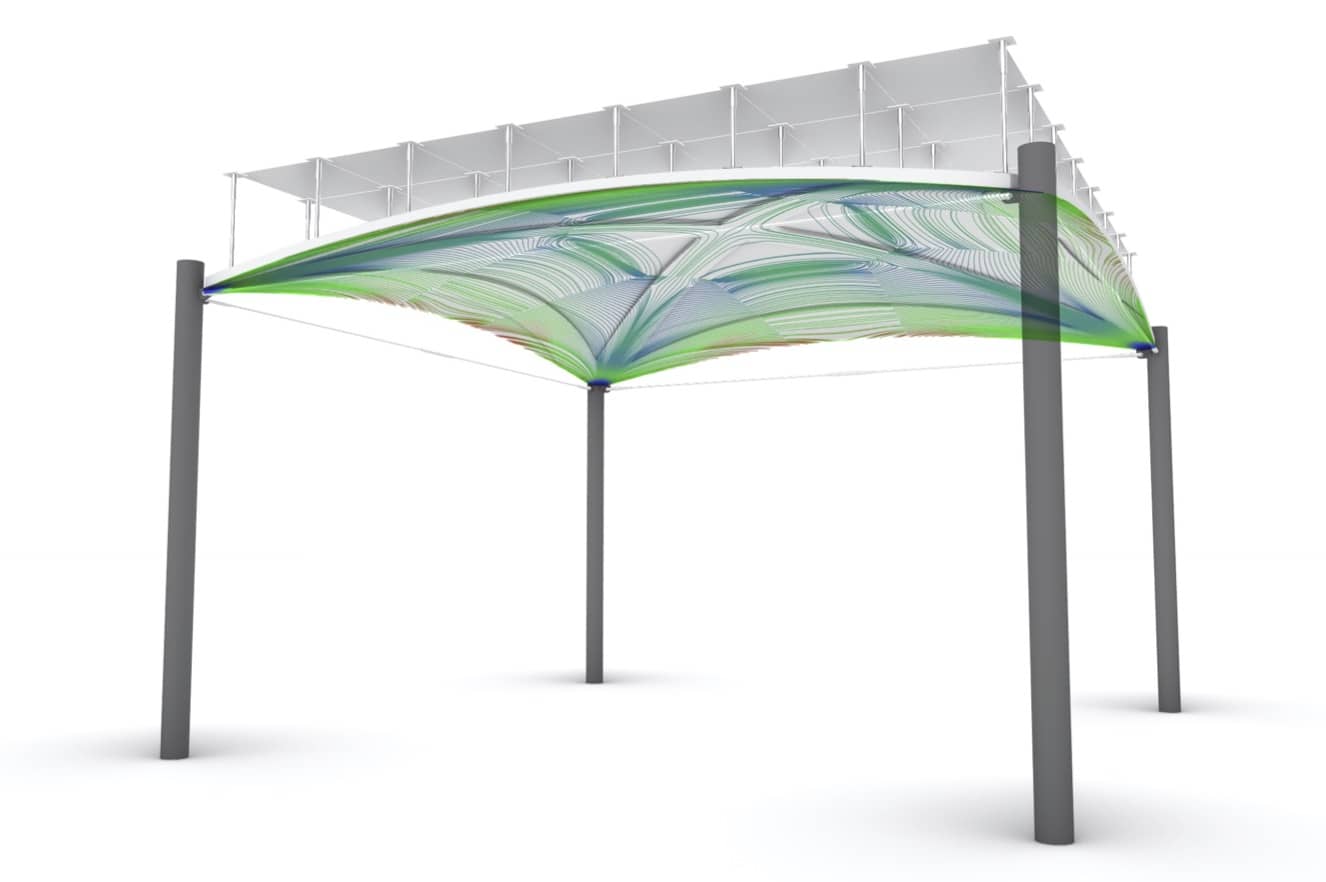

One result of the ACORN research is a thin concrete shell flooring system that uses a quarter of the concrete of an equivalent flat-slab with only 40% of the embodied carbon. The savings in carbon are not quite as high as the savings in concrete volume because the fabrication process requires additives to help the concrete flow through the spray system and also includes short strands of glass fibre reinforcement. However, the team are confident that the embodied carbon could be reduced even further by taking advantage of complementary innovations happening elsewhere to reduce the embodied emissions of concrete. For example, low-carbon cementitious materials are being developed, which could easily fit into an off-site automated manufacturing system. The ACORN team decided against adopting a 3D printing approach, because it is generally very slow and does not scale up to the mass-production context needed to really transform the industry. Instead, they combined a computer-controlled reconfigurable "pin-bed" formwork with a 6-axis robot arm fitted with a concrete and reinforcement-fibre spray system. They developed fabrication-aware software to assist with the design, analysis, optimisation and manufacture of the shells, which were made in transportable segments for later assembly on-site. Each of the nine separate pieces of their 4.5 x 4.5 m demonstrator took about half an hour to make.

The ACORN project is hoping to address connection details, material composition and carry out a more detailed study into Whole Life Value, so that their solution can be de-risked enough to be adopted by a manufacturer. The ideas around minimising material are quickly becoming accepted by industry, as a result of collaborations between academia and industry, as well as through collaborations amongst different industry organisations. Beyond building-elements such as beams and floors, there are concrete-intensive applications in bridges, highways, retaining walls, foundations and marine structures that could also benefit from such an approach.

Society's emphasis on embodied carbon and life cycle assessment will continue. This, together with accompanying regulation, will further accelerate the need to have a more frugal approach to the amount of materials in construction. Research and collaboration can provide useful alternatives for achieving a low-carbon society, but given the construction industry's historic resistance to change, it is likely to need informed clients and motivated governments to begin to demand such innovation, before innovative thin-shell concrete floors will be seen in an office near you any time soon.

References

Lehne, J. & Preston, F. (2018). Making Concrete Change: Innovation in Low-carbon Cement and Concrete. London: The Royal Institute of International Affairs. ISBN 978-1-78413-272-9.

UNEP (2022). Sand and Sustainability: 10 Strategic Recommendations to Avert a Crisis. Geneva: United Nations Environment Programme. ISBN: 978-92-807-3932-9.

Latest Peer-Reviewed Journal Content

Acceptability of sufficiency consumption policies by Finnish households

E Nuorivaara & S Ahvenharju

Key factors for revitalising heritage buildings through adaptive reuse

É Savoie, J P Sapinski & A-M Laroche

Cooler streets for a cycleable city: assessing policy alignment

C Tang & J Bush

Understanding the embodied carbon credentials of modern methods of construction

R O'Hegarty, A McCarthy, J O'Hagan, T Thanapornpakornsin, S Raffoul & O Kinnane

The changing typology of urban apartment buildings in Aurinkolahti

S Meriläinen & A Tervo

Embodied climate impacts in urban development: a neighbourhood case study

S Sjökvist, N Francart, M Balouktsi & H Birgisdottir

Environmental effects of urban wind energy harvesting: a review

I Tsionas, M laguno-Munitxa & A Stephan

Office environment and employee differences by company health management certification

S Arata, M Sugiuchi, T Ikaga, Y Shiraishi, T Hayashi, S Ando & S Kawakubo

Spatiotemporal evaluation of embodied carbon in urban residential development

I Talvitie, A Amiri & S Junnila

Energy sufficiency in buildings and cities: current research, future directions [editorial]

M Sahakian, T Fawcett & S Darby

Sufficiency, consumption patterns and limits: a survey of French households

J Bouillet & C Grandclément

Health inequalities and indoor environments: research challenges and priorities [editorial]

M Ucci & A Mavrogianni

Operationalising energy sufficiency for low-carbon built environments in urbanising India

A B Lall & G Sethi

Promoting practices of sufficiency: reprogramming resource-intensive material arrangements

T H Christensen, L K Aagaard, A K Juvik, C Samson & K Gram-Hanssen

Culture change in the UK construction industry: an anthropological perspective

I Tellam

Are people willing to share living space? Household preferences in Finland

E Ruokamo, E Kylkilahti, M Lettenmeier & A Toppinen

Towards urban LCA: examining densification alternatives for a residential neighbourhood

M Moisio, E Salmio, T Kaasalainen, S Huuhka, A Räsänen, J Lahdensivu, M Leppänen & P Kuula

A population-level framework to estimate unequal exposure to indoor heat and air pollution

R Cole, C H Simpson, L Ferguson, P Symonds, J Taylor, C Heaviside, P Murage, H L Macintyre, S Hajat, A Mavrogianni & M Davies

Finnish glazed balconies: residents' experience, wellbeing and use

L Jegard, R Castaño-Rosa, S Kilpeläinen & S Pelsmakers

Modelling Nigerian residential dwellings: bottom-up approach and scenario analysis

C C Nwagwu, S Akin & E G Hertwich

Mapping municipal land policies: applications of flexible zoning for densification

V Götze, J-D Gerber & M Jehling

Energy sufficiency and recognition justice: a study of household consumption

A Guilbert

Linking housing, socio-demographic, environmental and mental health data at scale

P Symonds, C H Simpson, G Petrou, L Ferguson, A Mavrogianni & M Davies

Measuring health inequities due to housing characteristics

K Govertsen & M Kane

Provide or prevent? Exploring sufficiency imaginaries within Danish systems of provision

L K Aagaard & T H Christensen

Imagining sufficiency through collective changes as satisfiers

O Moynat & M Sahakian

US urban land-use reform: a strategy for energy sufficiency

Z M Subin, J Lombardi, R Muralidharan, J Korn, J Malik, T Pullen, M Wei & T Hong

Mapping supply chains for energy retrofit

F Wade & Y Han

Operationalising building-related energy sufficiency measures in SMEs

I Fouiteh, J D Cabrera Santelices, A Susini & M K Patel

Promoting neighbourhood sharing: infrastructures of convenience and community

A Huber, H Heinrichs & M Jaeger-Erben

New insights into thermal comfort sufficiency in dwellings

G van Moeseke, D de Grave, A Anciaux, J Sobczak & G Wallenborn

'Rightsize': a housing design game for spatial and energy sufficiency

P Graham, P Nourian, E Warwick & M Gath-Morad

Implementing housing policies for a sufficient lifestyle

M Bagheri, L Roth, L Siebke, C Rohde & H-J Linke

The jobs of climate adaptation

T Denham, L Rickards & O Ajulo

Structural barriers to sufficiency: the contribution of research on elites

M Koch, K Emilsson, J Lee & H Johansson

Disrupting the imaginaries of urban action to deliver just adaptation [editorial]

V Castán-Broto, M Olazabal & G Ziervogel

Nature for resilience reconfigured: global- to-local translation of frames in Africa

K Rochell, H Bulkeley & H Runhaar

How hegemonic discourses of sustainability influence urban climate action

V Castán Broto, L Westman & P Huang

Fabric first: is it still the right approach?

N Eyre, T Fawcett, M Topouzi, G Killip, T Oreszczyn, K Jenkinson & J Rosenow

Social value of the built environment [editorial]

F Samuel & K Watson

Understanding demolition [editorial]

S Huuhka

Data politics in the built environment [editorial]

A Karvonen & T Hargreaves

Latest Commentaries

Decolonising Cities: The Role of Street Naming

During colonialisation, street names were drawn from historical and societal contexts of the colonisers. Street nomenclature deployed by colonial administrators has a role in legitimising historical narratives and decentring local languages, cultures and heritage. Buyana Kareem examines street renaming as an important element of decolonisation.

Integrating Nature into Cities

Increasing vegetation and green and blue spaces in cities can support both climate change mitigation and adaptation goals, while also enhancing biodiversity and ecological health. Maibritt Pedersen Zari (Auckland University of Technology) explains why nature-based solutions (NbS) must be a vital part of urban planning and design.